Caustic Cracking Of Steel Torent

Caustic cracking is a form of stress corrosion cracking most frequently encountered in carbon steels or iron-chromium-nickel alloys that are exposed to concentrated hydroxide solutions at temperatures of 482°F (250°C). Example Program For Datagridview In Vb.net. This phenomenon mostly occurs in boilers where caustic soda (NaOH) has been added in small amounts to boiler water to prevent scaling. However, caustics (alkalis) may become concentrated amounts in crevices around rivet heads and at hot spots. When combined with the considerable fabrication stresses around rivet holes, this can cracking of the steel boiler shells and tube plates. Caustic cracking is also known as caustic embrittlement. The following conditions are necessary for this type of cracking to occur: • The metal must be stressed • The boiler water must contain caustics • At least a trace of silica must be present • Some mechanisms, such as a slight leak, must be present to allow the boiler water to concentrate on the stressed metal Caustic cracking can be prevented through: • Control of stress level (residual or load) and hardness • Avoiding alkalis • Use of materials known not to crack in the specified environment • Controlling temperature and/or potential.

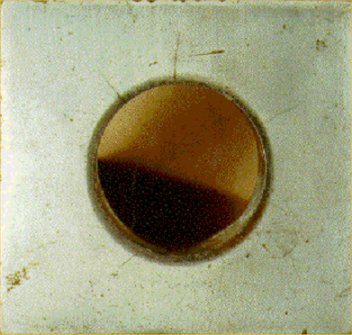

Figure 2 shows caustic cracking of a carbon steel pipe. Ferritic Stainless Steels. The high purity ferritic stainless steels, such as E-Brite 26-1 (UNS. Both 304 and 316 stainless steel types are resistant to a wide. C Program Files Google Update Googleupdate Exe Medsvc. Risk of stress corrosion cracking attack 'Caustic stress corrosion cracking' occurs at higher.

• 219 Downloads • Abstract The stress corrosion cracking (SCC) behavior of cold worked mild steel in hot, aqueous, 33 pct NaOH solutions was studied with prefatigue cracked double cantilever beam specimens. SCC kinetics were studied under freely corroding potentials ( E corr ≈ −1.00 V SHE) and potentiostatic potentials of −0.76 V SHE near the active-passive transition. The pH of the liquid within the crack was determined and fractography was studied by scanning electron microscopy. Cracking was transgranular at E corr, intergranular at −0.76 V SHE, and produced no detectable change in crack liquid pH from that of the bulk solution. Crack rates were dependent upon temperature, potential, and stress intensity ( K 1).

Comments are closed.